Sep. 21, 2018

Flush Grid Belt, also known as silent chains, are a way of categorizing the drive train. It is widely used in important mechanical basic parts, and is mainly used in high-speed, heavy-duty, low-noise, large-center moments, and its transmission function is superior to toothed belt transmission, gear transmission and chain drive. The chain has now become one of the preferred transmission methods in many industries.

The Plastic Hold-down Belt has the characteristics of low noise. The toothed chain is occluded and transmitted through the involute tooth shape of the working chain plate and the sprocket teeth. Compared with the chain of the chain and the chain of the sleeve, the polygonal effect is significantly reduced. The movement is smooth and the bite noise is very small. The toothed chain also has a high reliability feature. The chain link of the toothed chain is a multi-piece structure. When a single chain is damaged during operation, it does not affect the operation of the entire chain. It can be found and replaced in time. If it is necessary to add bearing capacity, it is only necessary to add the number of rows of the chain at the foot scale in the width direction. In addition, the toothed chain also has the characteristics of high motion precision, and the chain links of the toothed chain are relatively uniform in wear and elongation, so that high motion precision can be adhered to. The main types of the chain are: textile machinery and centerless grinding machines, conveyor belt machinery and equipment. The types of toothed chains are: CL06, CL08, CL10, CL12, CL16, and CL20. According to the guide classification, it is divided into three types: an inner guide tooth-shaped chain and an outer guide tooth-shaped chain, and an inner and outer conformal tooth-shaped chain.

Previous: Advantage Of Perforated Top Belt

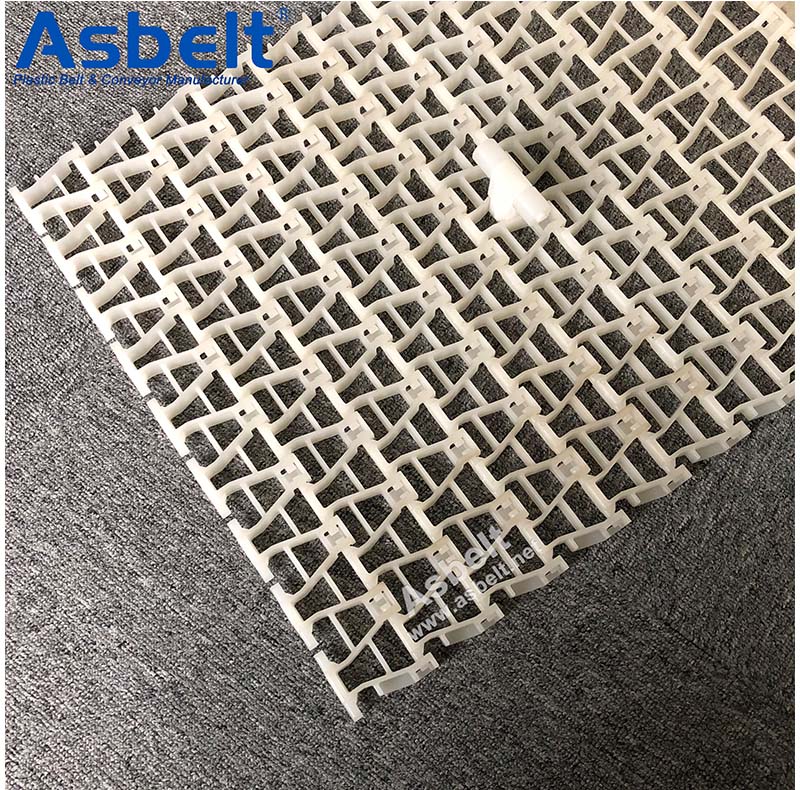

Next: About Flush Grid Belt

Tel: +86 216 788 1607

Mobile: +86 13611607740

E-mail: shanliang@asbelt.net

WhatsApp: +86 136 1160 7740