Sep. 28, 2018

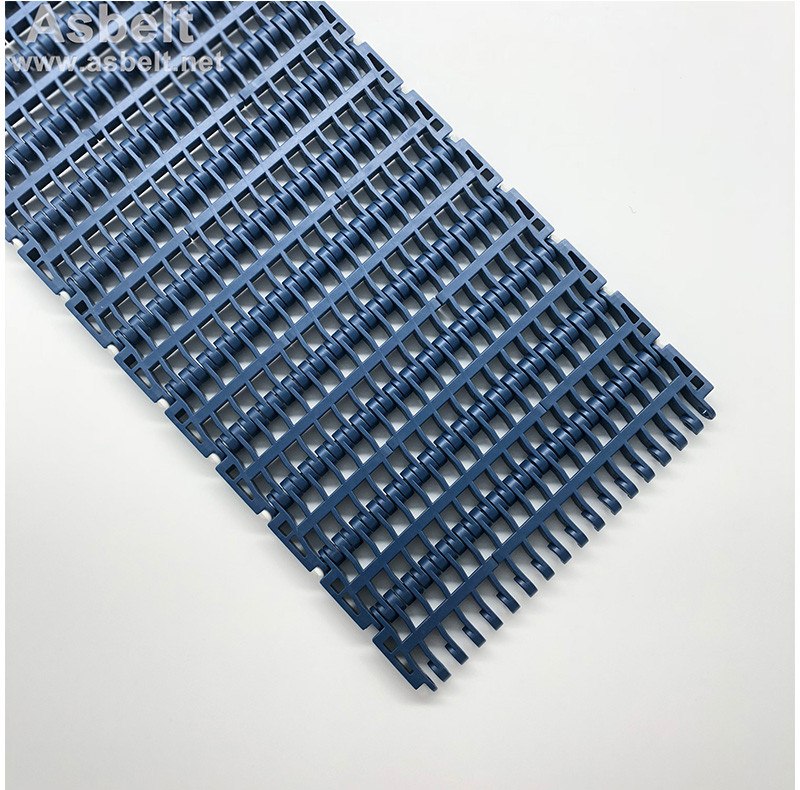

Flush Grid Belt are used for the transport of heavy parts, often used in washing machine conveyors, sterilization conveyors, screw conveyors, dairy and beverage industries, baking lines, fruit and vegetable industries, aquatic products and meat processing industries, container manufacturing industries, Corrugated board processing industry, battery industry, snack processing industry, general material transportation. The plastic chain plate is a kind of conveying assembly equipment that uses the special bending plate chain as the transmission medium to drive the metal/plastic panel to reciprocate. Because the wire structure and the conveying medium are relatively strong, it is generally used in the transportation and assembly work of heavier articles, and the load capacity per metre can reach 500Kg. The conveying speed of the Plastic Washer Belt body is adjustable, and there are various speed control modes such as electromagnetic speed regulation, frequency conversion speed regulation, mechanical speed regulation, etc.

Generally, the fastest speed is within 15M/min. Due to the working environment and the needs of the production process, the wire body can also be made into a 90-degree or 180-degree turn type, which is used for vacuuming of air-conditioning chain conveyors, refrigerator chain plate chain machines, power tool chain conveyors, etc. And testing. Various fixtures can be set on the panel to meet the clamping, rotation, assembly and inspection of the workpiece. In the case of the need to protect the surface of the workpiece, the panel can be made of plastic or glued on the surface of the metal panel. The main structure of the line body mainly has a steel frame structure and an aluminum profile structure.

Previous: Introduction Of Perforated Top Belt

Tel: +86 216 788 1607

Mobile: +86 13611607740

E-mail: shanliang@asbelt.net

WhatsApp: +86 136 1160 7740