Oct. 31, 2018

Before the Perforated Top Modular Belt was developed, all the conveyors were transported by belt, but there were many big problems in the use of the conveyor. For example, belt conveyor is easy to go wrong, this is recognized in the industry, and can not be avoided. The material conveyed by the conveyor during work is rubbed with the conveyor belt all the year round, so that the belt cannot be broken during use. Due to the particularity of the belt, if the entire belt is only rotted in one place, the whole belt It has to be changed, which has greatly increased the cost of the enterprise and greatly wasted resources.

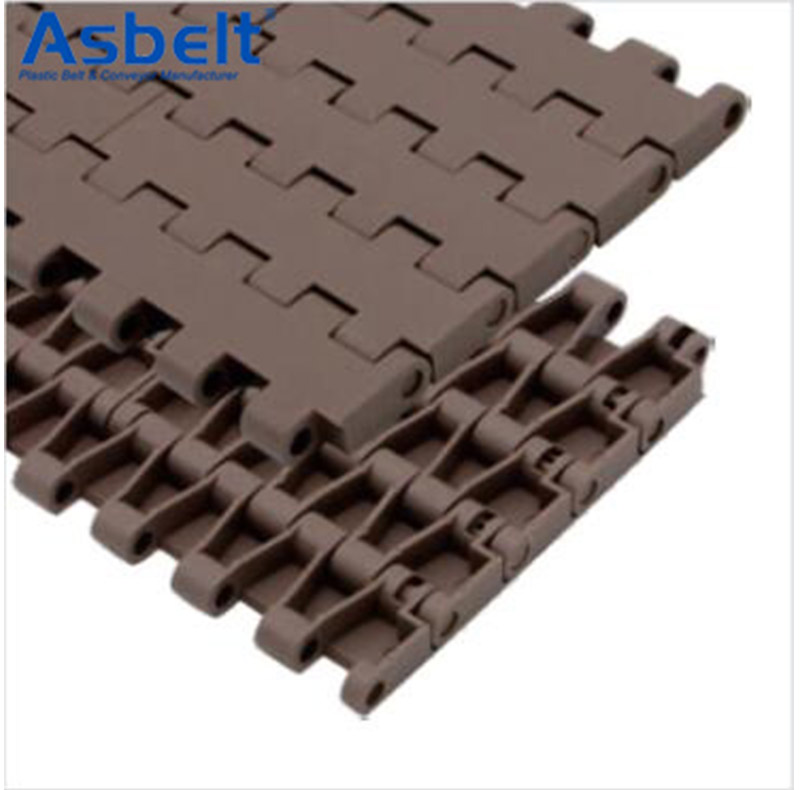

The Plastic Flat Top Belt solves all the drawbacks of the belt. Everyone knows that the plastic mesh belt is made up of a piece of independent modules. If there is damage in one place during use, the plastic mesh belt can be taken apart and re-opened. It is enough to change a separate module. It does not require a large area to be replaced. This will bring good production efficiency to the enterprise and greatly reduce the production cost of the production enterprise.

Due to the special structure of the plastic mesh belt, it will not go off at all during operation. The transmission mode of the plastic mesh belt is very special. It is fixedly driven by the back sprocket. Each sprocket has a fixed sprocket hole position, and the sprocket hole position of the plastic mesh belt plays a limiting role, so the plastic mesh belt is in the When the work is running, it will not go wrong.

Tel: +86 216 788 1607

Mobile: +86 13611607740

E-mail: shanliang@asbelt.net

WhatsApp: +86 136 1160 7740